News Center

0512-52836238

0512-52836128

0512-52358728

Sales Department Fax

0512-52836278

Sales Department Email

xu@worldbrom.com

Purchasing Department Tel/ Fax

0512-52836228

Headquarters Address US Office

, No. 18 Haitian Road, Advanced Material Industrial Park, Changshu City, Jiangsu

Tel

+1 832-857-1028

U.S. office mailbox

Lauren@worldbrom.com

shelia@worldbrom.com

U.S. office address

Creekside Park, The Woodlands, Texas 77375, USA

corporate website

www.worldbrom.com

Procurement Hotline

0512-52836128Sources:www.worldbrom.com | PublishDate:2025.11.25

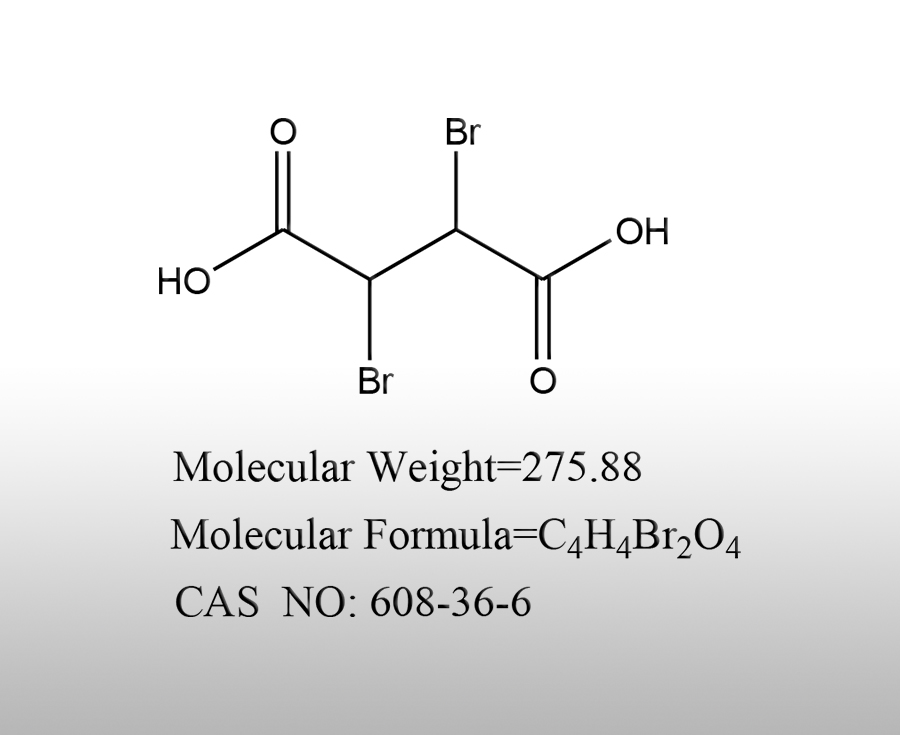

Dibromosuccinic acid (DBSA), as a bromine containing organic compound, has demonstrated significant advantages in flame retardancy, organic synthesis, water treatment, and other fields due to its unique chemical structure and physicochemical properties. The core advantages revolve around three dimensions: "high efficiency functionality, environmental compatibility, and application adaptability", as follows:

1、 Excellent flame retardant performance, suitable for flame retardant needs in multiple scenarios

Efficient bromine based flame retardant, high flame retardant efficiency: The molecular structure contains bromine content of over 56% (theoretical value). Bromine is a typical flame retardant element, which can release bromine free radicals during combustion, capture active free radicals in the combustion chain reaction, and suppress flame spread; The hydrogen bromide gas produced by simultaneous decomposition can dilute oxygen, isolate heat, and form a dual flame retardant system. With a low addition amount (usually 5% -15%), it can meet the UL94 V-0 flame retardant standard and is suitable for various substrates such as plastics, rubber, textiles, etc.

Wide flame retardant range and strong compatibility: compatible with general plastics such as PP, PE, ABS, PVC, as well as composite materials such as epoxy resin and polyurethane, without affecting the processing fluidity and mechanical properties of the substrate; It can be used alone as a flame retardant or in combination with antimony based synergists (such as antimony trioxide) to further enhance the flame retardant effect without producing significant toxic gases. Compared with traditional bromine based flame retardants (such as polybrominated biphenyls), it has a lower density.

Good thermal stability and strong processing adaptability: the decomposition temperature is about 240 ℃, which is higher than the processing temperature of most polymer materials (150-220 ℃). It is not easy to decompose and evaporate during injection molding, extrusion, spinning and other processing processes, and can maintain stable flame retardant properties; And during the long-term use of the material, it is not easy to migrate and precipitate, ensuring the durability of the flame retardant effect.

2、 High chemical activity, it is a high-quality intermediate for organic synthesis

Functional groups have strong reactivity and diverse synthesis pathways: the molecule contains two bromine atoms (halogenated groups) and two carboxyl groups (acidic groups) simultaneously. Bromine atoms are prone to nucleophilic substitution reactions (such as reactions with amines and alcohols), while carboxyl groups can undergo esterification, amidation, condensation, and other reactions, making them key intermediates for synthesizing various functional compounds.

Suitable for synthetic scenarios: can be used to synthesize flame retardant plasticizers, antistatic agents, pharmaceutical intermediates (such as precursors for specific antibiotics and anti-inflammatory drugs), pesticide intermediates (such as highly effective and low toxicity insecticides), etc; Especially in the synthesis of bromine containing functional polymer materials, flame retardant groups can be introduced into the molecular chain through chemical bonding, avoiding the migration of flame retardants and improving the long-term stability of the material.

3、 Better environmental and usage safety, in line with environmental trends

Low toxicity, low pollution, and no persistent organic pollutants (POPs) characteristics: Compared with traditional brominated flame retardants (such as polybrominated diphenyl ethers and hexabromocyclododecane), dibromosuccinic acid does not have bioaccumulation and long-distance migration, is easily degraded in the environment (can be decomposed into harmless substances by Microbes in soil and water), and has low acute toxicity to aquatic creatures and mammals (LD50>2000 mg/kg), complying with environmental standards such as EU RoHS and REACH, with fewer usage restrictions.

Non corrosive and easy to use: It is a white crystalline powder at room temperature, with lower irritability than similar halogenated carboxylic acids. It is non corrosive to equipment and substrates and can be directly mixed and processed with materials without special anti-corrosion treatment; And there is no obvious odor or harmful gas release during the processing, making the working environment more friendly.

4、 Other functional advantages, expanding application scenarios

Moisture absorption and moisturizing performance, suitable for daily chemical and material modification: The carboxyl group in the molecule has a certain hydrophilic group, which can absorb moisture from the air and be used as a moisturizer for daily chemical products (such as skincare and hair conditioners), or to modify the hydrophilicity of polymer materials to enhance their anti-static performance.

Metal chelating ability, auxiliary water treatment: The synergistic effect of carboxyl and bromine atoms gives it a certain chelating ability for some metal ions (such as copper, iron, lead, etc.), which can be used as an auxiliary component of water treatment agents to remove heavy metal ions from industrial wastewater or prevent metal ions from catalyzing material aging.

Controllable cost and high cost-effectiveness: The synthesis process is relatively mature (can be prepared through the addition reaction of maleic acid and bromine), the raw materials are easily available (maleic acid and bromine are both bulk chemical raw materials), and the production cost is lower than similar flame retardants and organic intermediates. It has significant cost-effectiveness advantages in medium application scenarios.